Copper Coin Technology for Advanced Thermal Management in PCBs

At Daleba, we offer cutting-edge Copper Coin technology to optimise thermal management in PCBs. Copper, with its exceptional thermal conductivity exceeding 400 W/mK, is one of the most effective materials for controlling heat while maintaining both electrical and thermal conductivity.

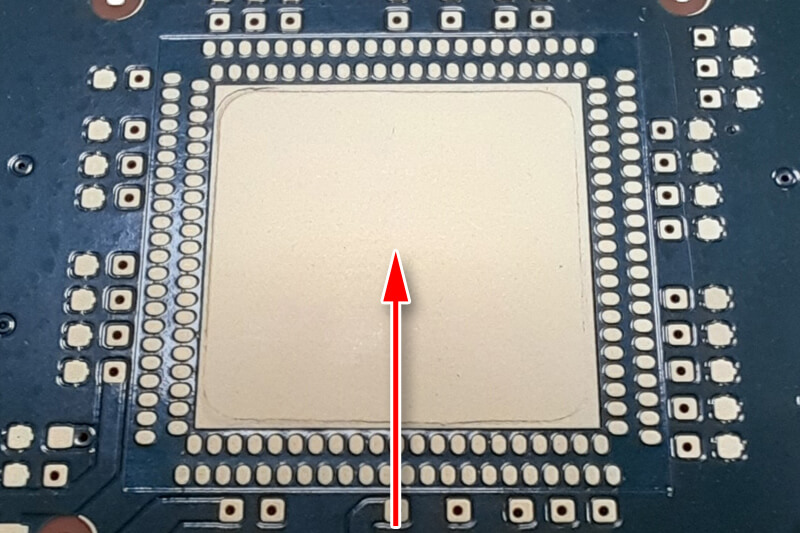

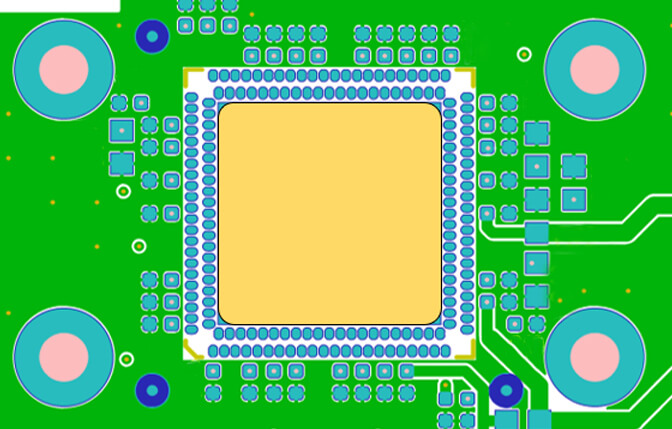

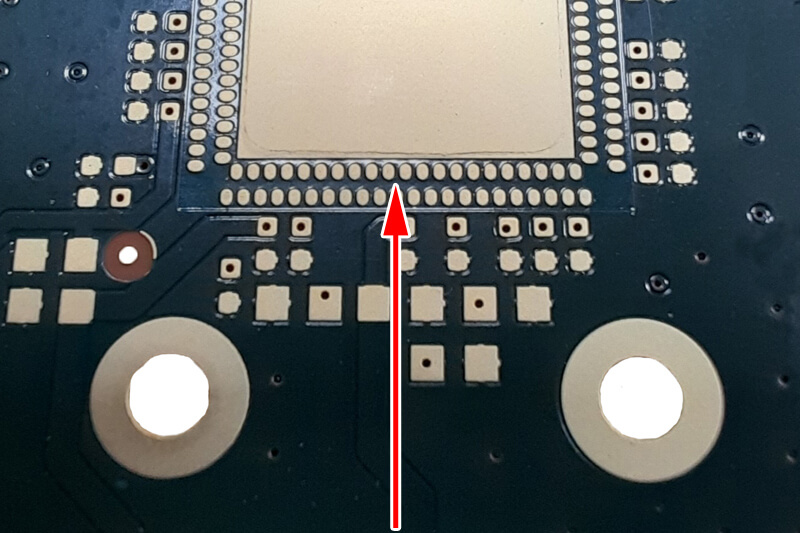

Solid Copper Coin

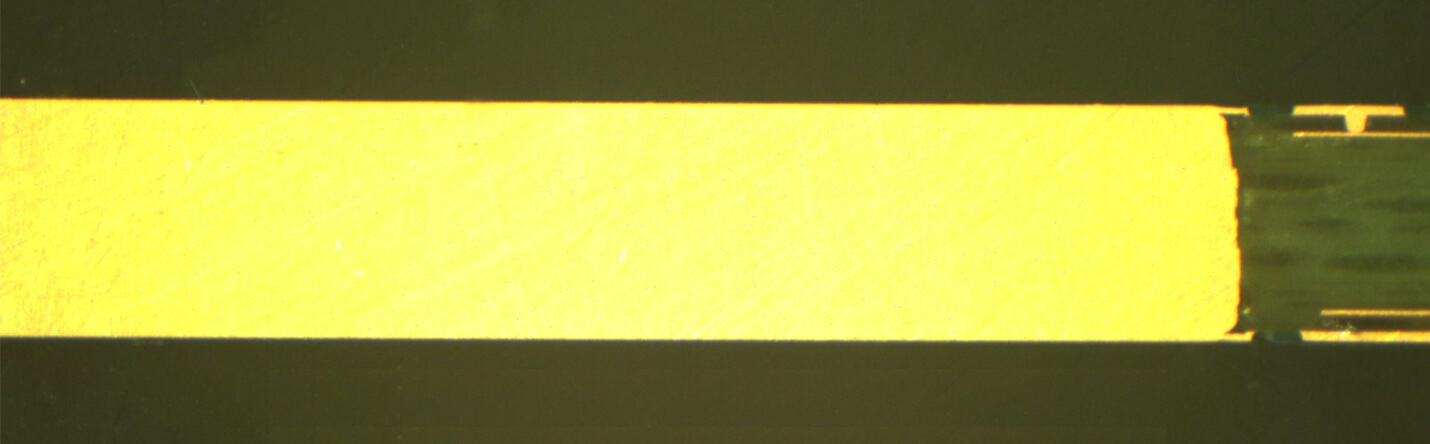

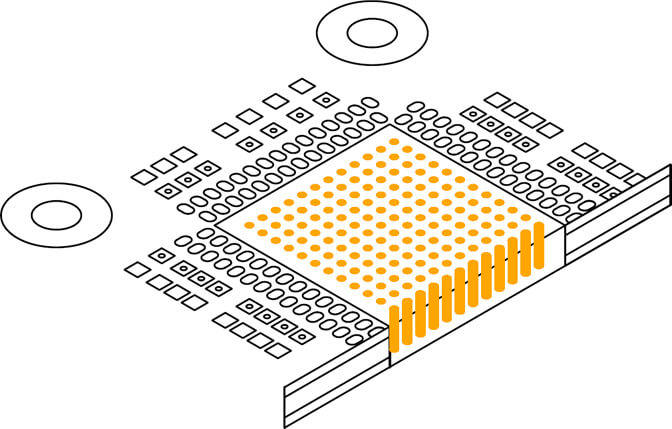

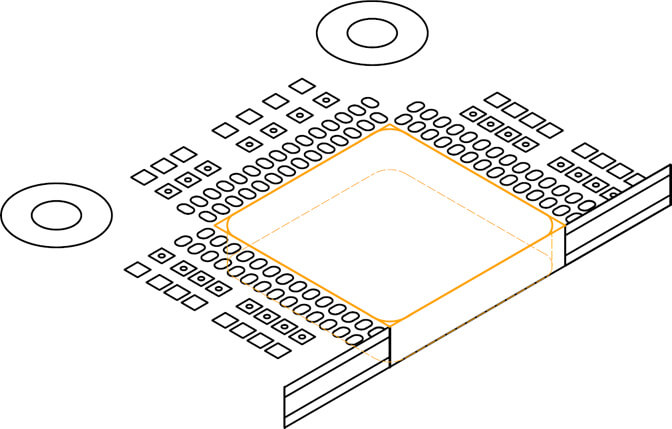

Solid Copper Coin Cross Section of Copper Coin

Cross Section of Copper CoinWhat is Copper Coin Technology?

A copper coin is a solid piece of copper integrated into the PCB, typically positioned directly beneath heat-generating components. This strategic placement significantly enhances heat dissipation compared to traditional thermal via arrays, delivering nearly double the cooling efficiency.

In addition to superior heat management, copper coins can establish direct contact between the heat-generating component pad and the heat sink, eliminating the need for less effective thermally conductive materials. Copper's thermal conductivity outperforms conventional conductive dielectric prepregs by 50 to 200 times, making it the ideal solution for targeted cooling.

Optimal Application and Versatility

Copper Coin technology excels in PCBs with localized heat sources, especially when one or a few components generate the majority of the heat. Regardless of the PCB's layer count, copper coins provide unparalleled localised heat transfer, making them the go-to solution for demanding thermal management challenges.

Manufacturing Excellence at Daleba

When manufacturing Copper Coin PCBs, Daleba utilises high-purity, electrical-grade C103 copper. This grade is chosen for its superior electrical conductivity and resistance to hydrogen embrittlement, ensuring both reliability and performance.

The copper coin can be embedded through the entire board, exposing it on both sides, or inserted from one side, depending on design requirements. This flexibility allows the copper coin to efficiently dissipate high levels of heat from components mounted above or below it.

Seamless Integration with Other Technologies

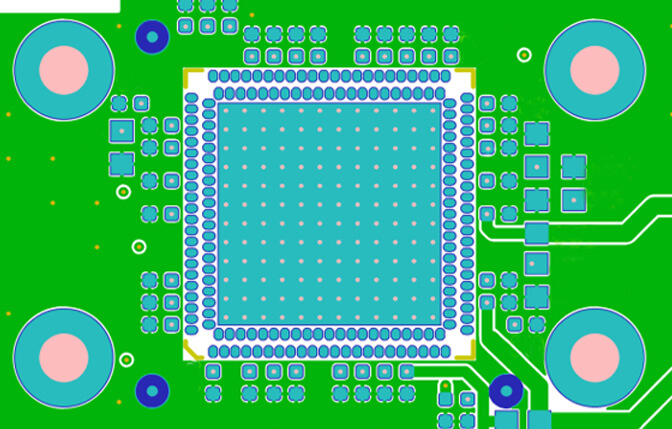

Depending on individual requirements, our Copper Coin technology can be combined with other solutions, such as copper-filled vias, to tackle even the most complex board designs. By integrating these technologies, we can deliver tailored solutions that meet the highest standards of thermal performance.

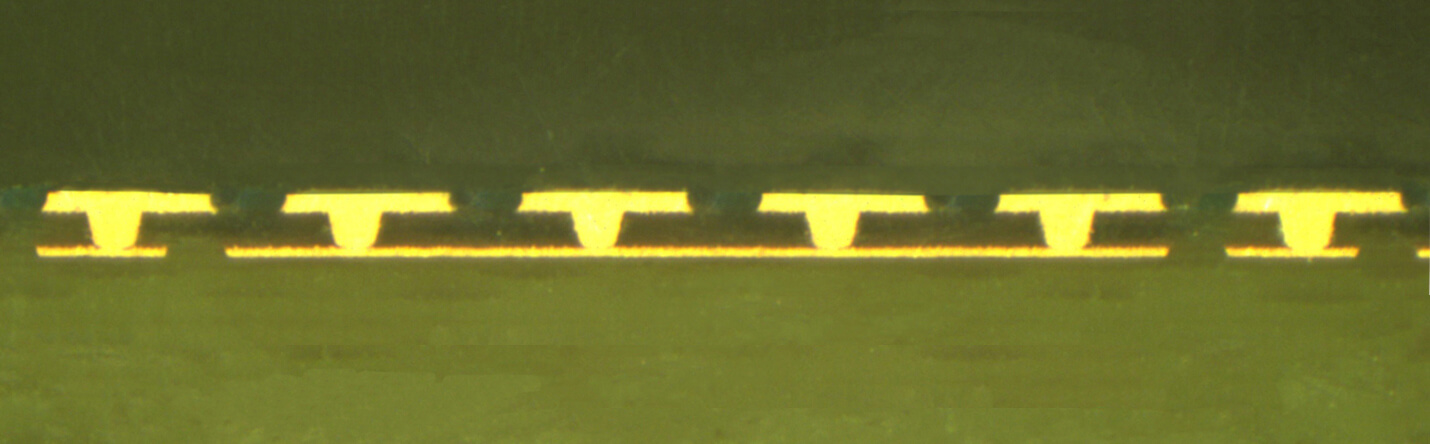

Copper filled blind vias

Copper filled blind vias Cross Section of Copper Filled Vias

Cross Section of Copper Filled ViasSign up to receive a monthly PCB newsletter containing the latest information in the world of PCBS including new technology and supply chain information.

Sign up Now