Flex and Rigid-Flex PCBs will include some degree of flexibility. This can be in the whole circuit (Flex) or a dynamic flexible join between two or more rigid boards (Rigid-Flex). The main advantage is often considered as having the ability to physically fit into products where no other solution would work but they have many other advantages.

Advantages include:

DK-Daleba is a leading supplier of Flex and Rigid Flex circuit, and we can manufacture your boards in a wide range of materials and surface finishes depending on your exact application. Full capabilities are detailed below, and a pdf can be downloaded here.

Contact us today and our sales engineers will discuss your exact requirement Download Flex / Flex-Rigid Brochure

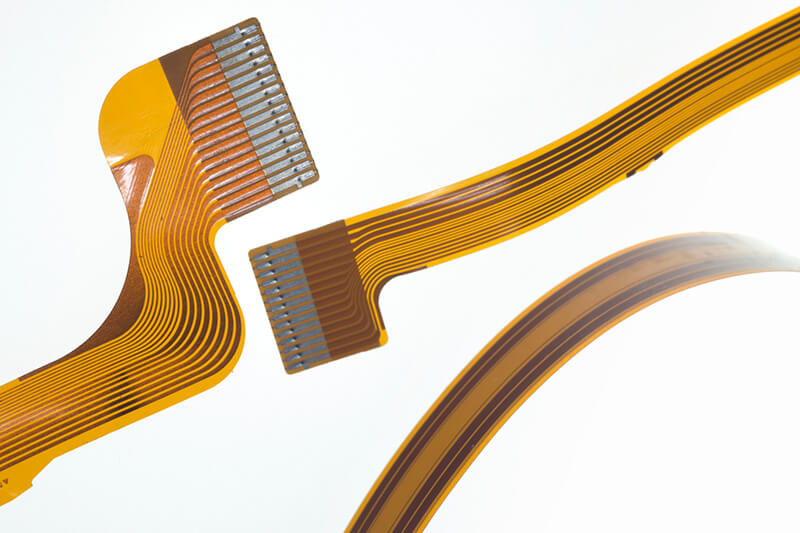

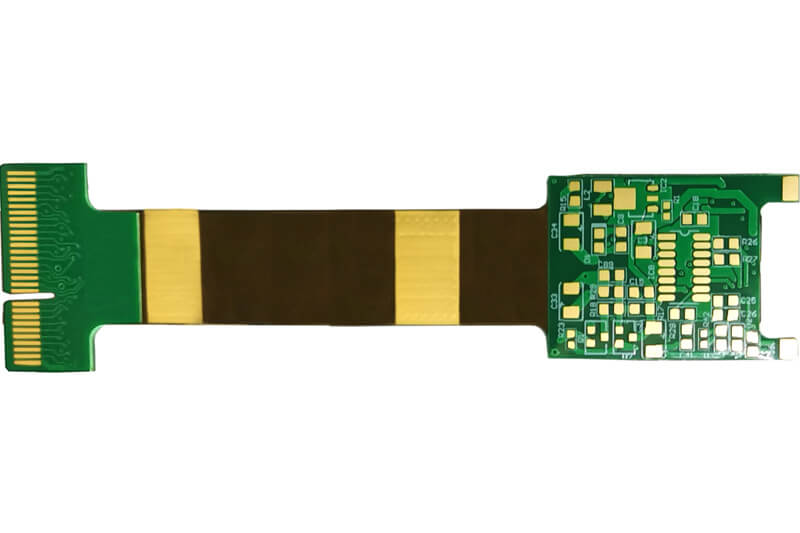

Flex circuits are also referred to as a FPC (Flexible Printed Circuit), Flex Circuit Boards, Flex PCBs, Flex Circuits, or Flexible Printed Circuits. They consist of a thin insulating polymer film encapsulating the conductor circuit. Polyimides are popular for construction as they offer high temperature opportunities for assembly or product environment. Flex circuits can be manufactured as a connector or designed for use with components. Rigid stiffeners can be included. They can be constructed as single sided, double sided or multi-layered.

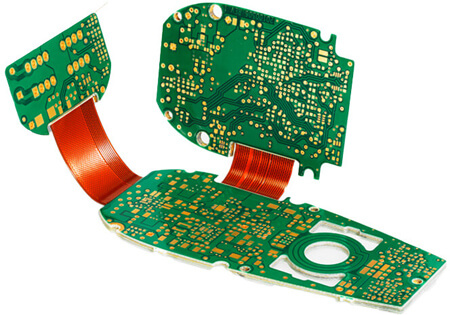

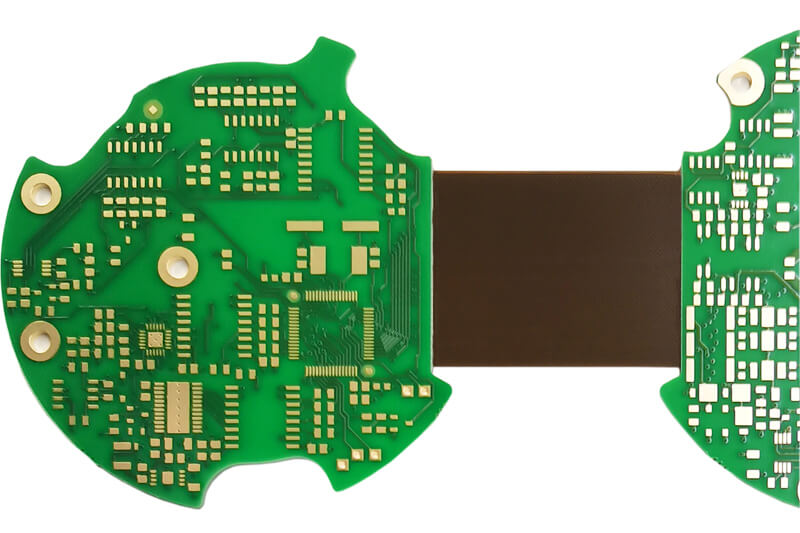

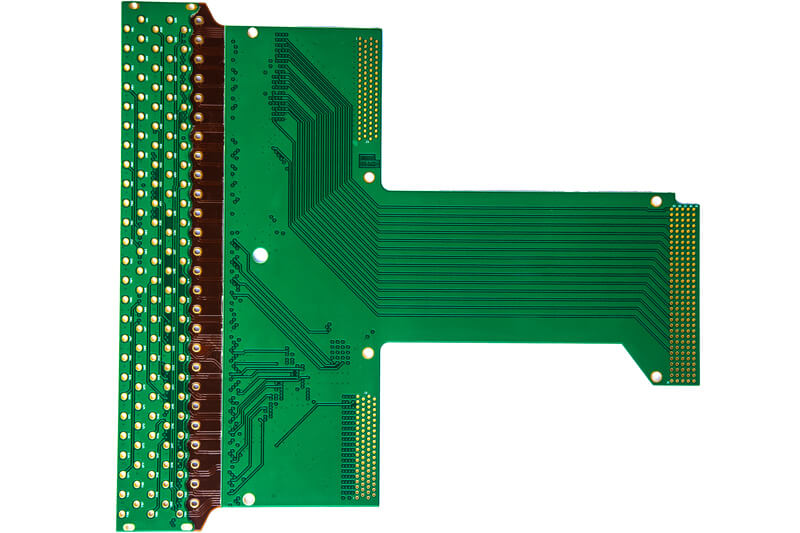

Rigid Flex are hybrid boards and by definition consist of a Flex board with a Rigid circuit component incorporated in the design. These hybrid circuits can be a Flex with an FR4 stiffener, or two or more rigids connected with Flex circuits. Rigid Flex circuits offer the best of both flexible circuits and rigid boards combined in one PCB.

Rigid Flex circuits are extremely versatile and can be used in a wide range of applications. Designers often consider they are ultimate solution for making use of the available packaging space. Increased product reliability and overall reduced assembly costs are also drivers for this technology.

Sign up to receive a monthly PCB newsletter containing the latest information in the world of PCBS including new technology and supply chain information.

Sign up Now